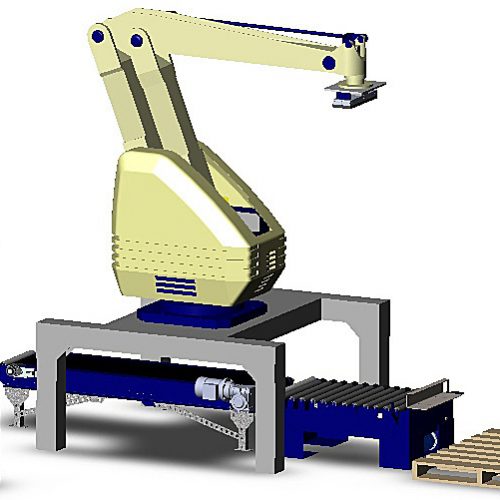

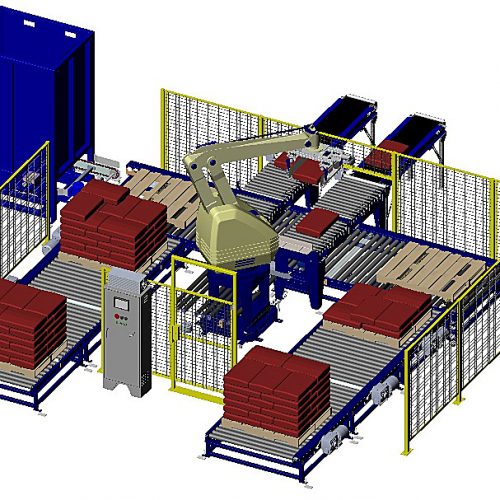

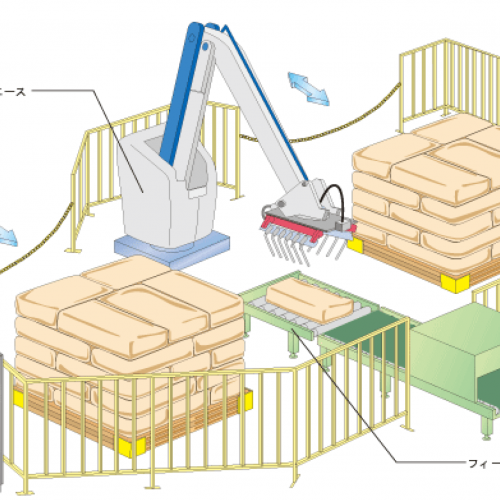

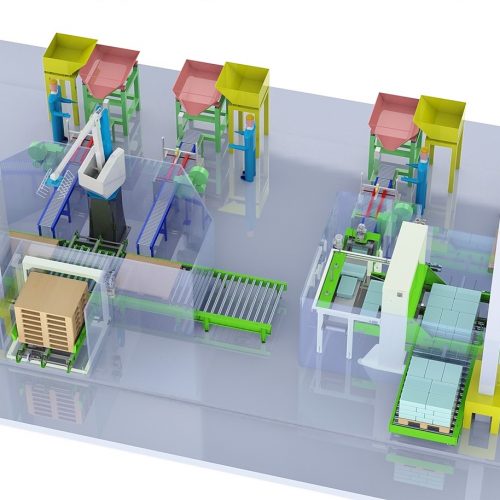

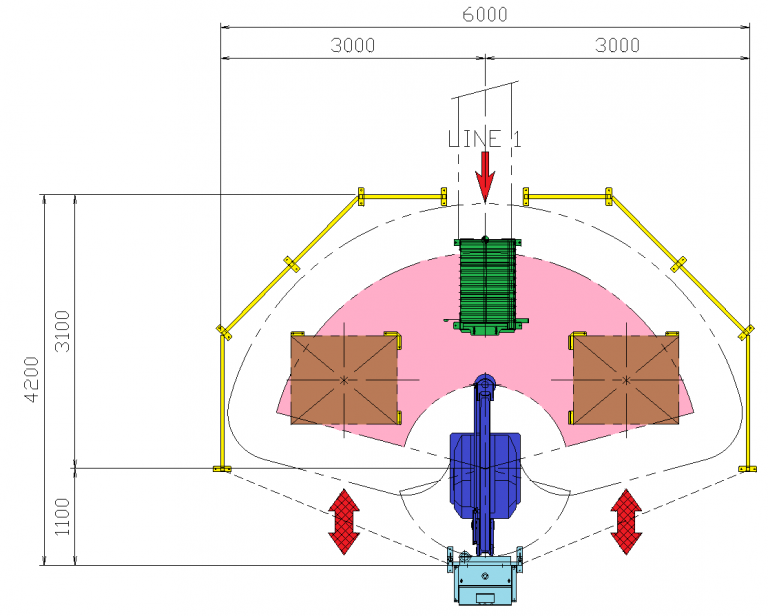

Bag/Sack Palletizing

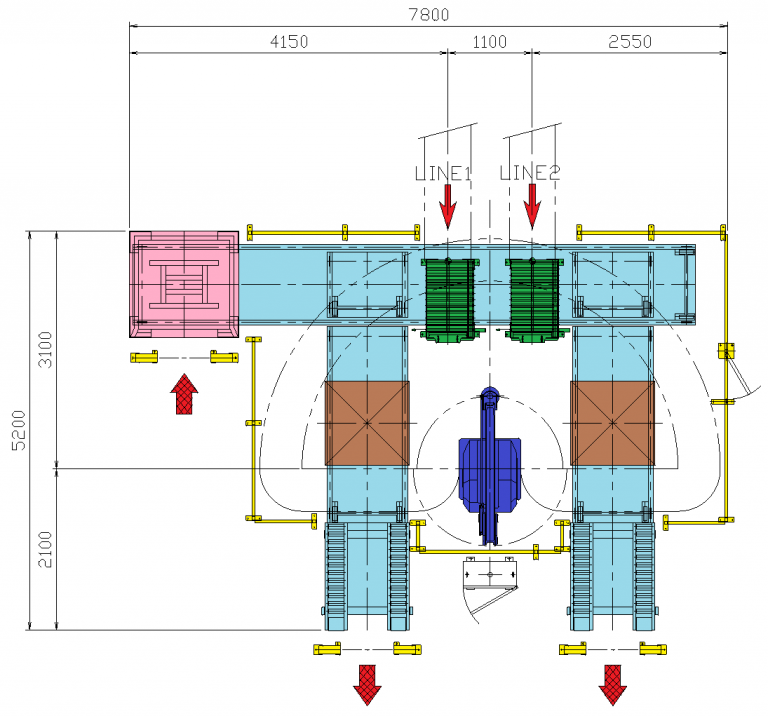

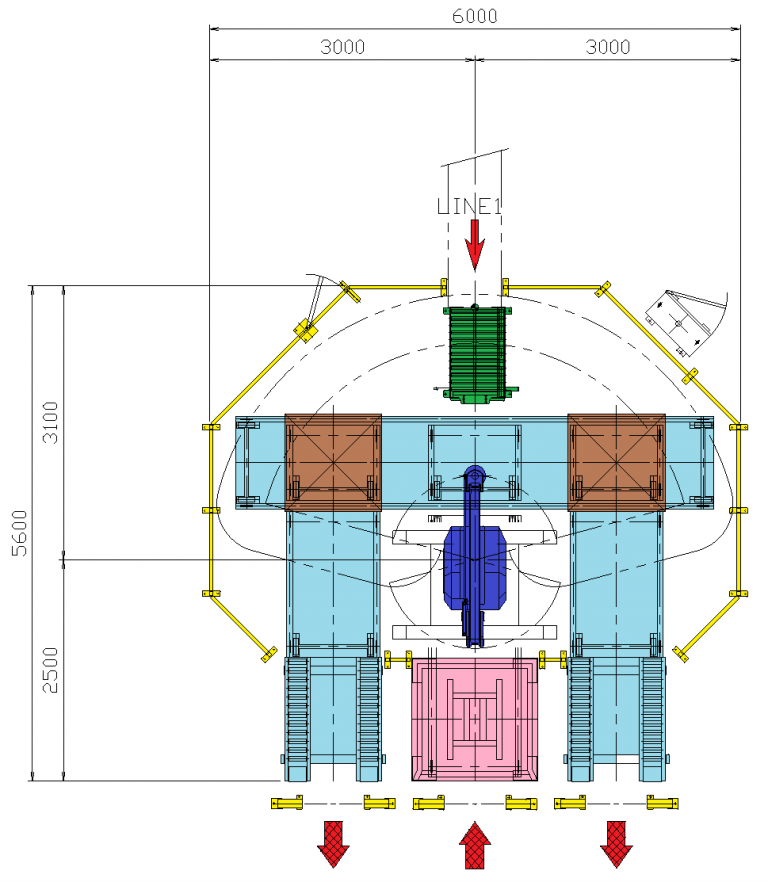

Fuji Robot palletizers are specialized for sack handling. Choose from one of our preloaded palletizing patterns and achieve an output up to 30 bags/minute

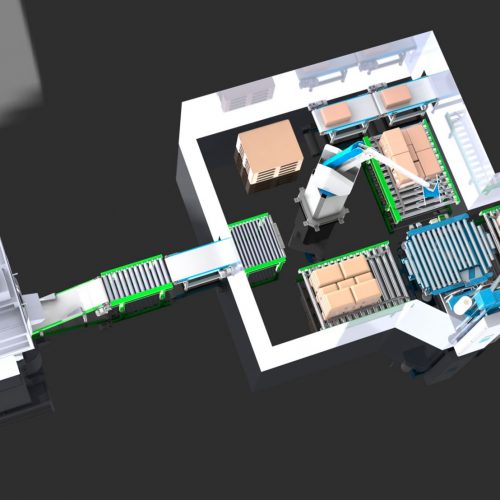

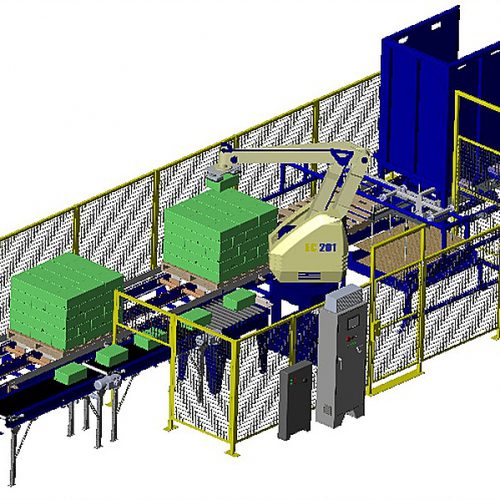

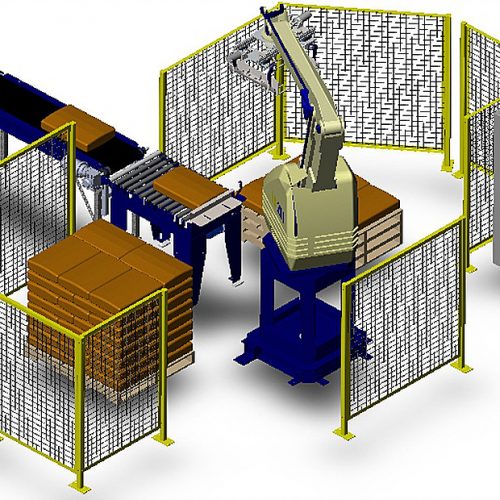

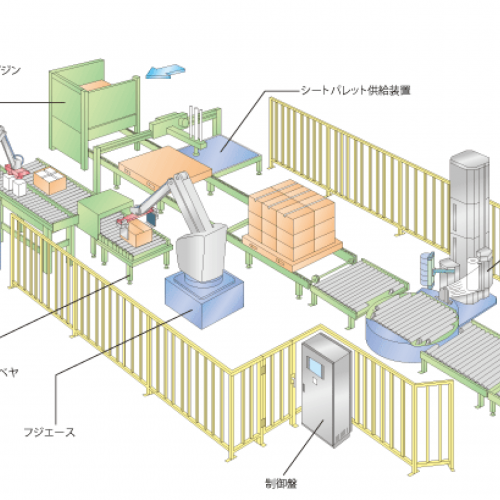

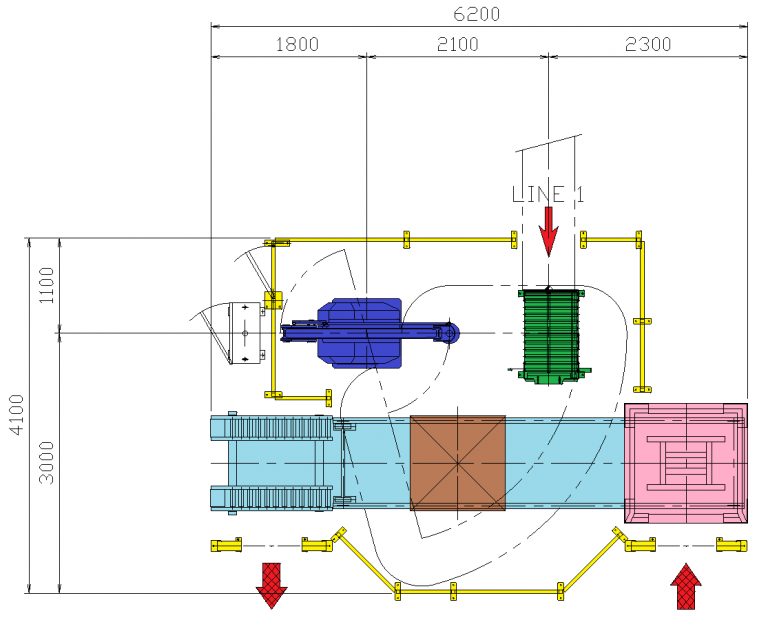

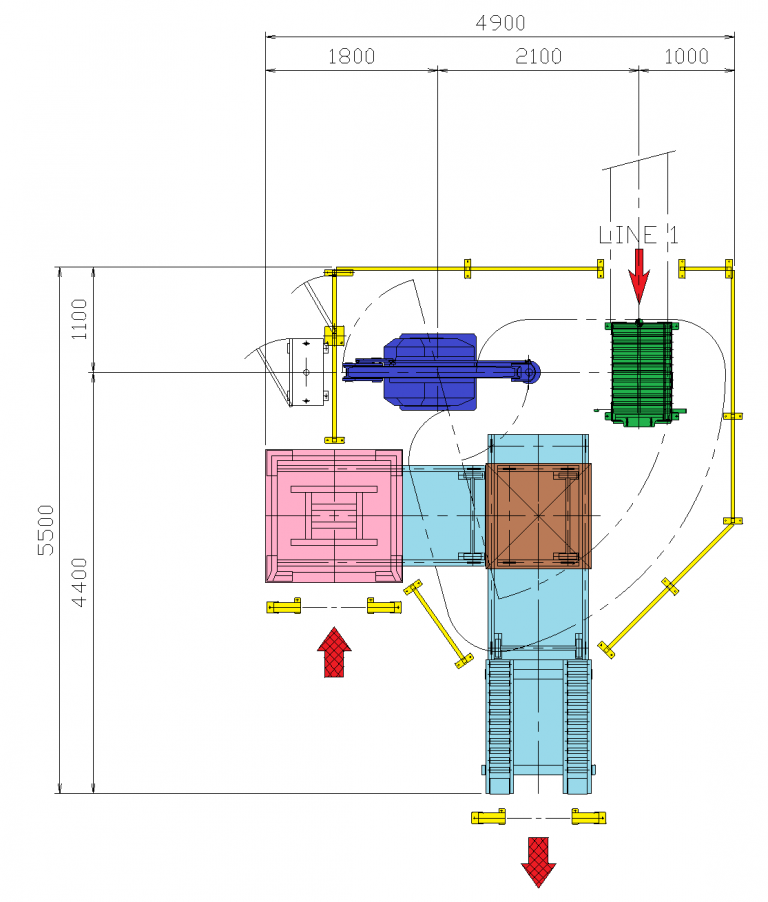

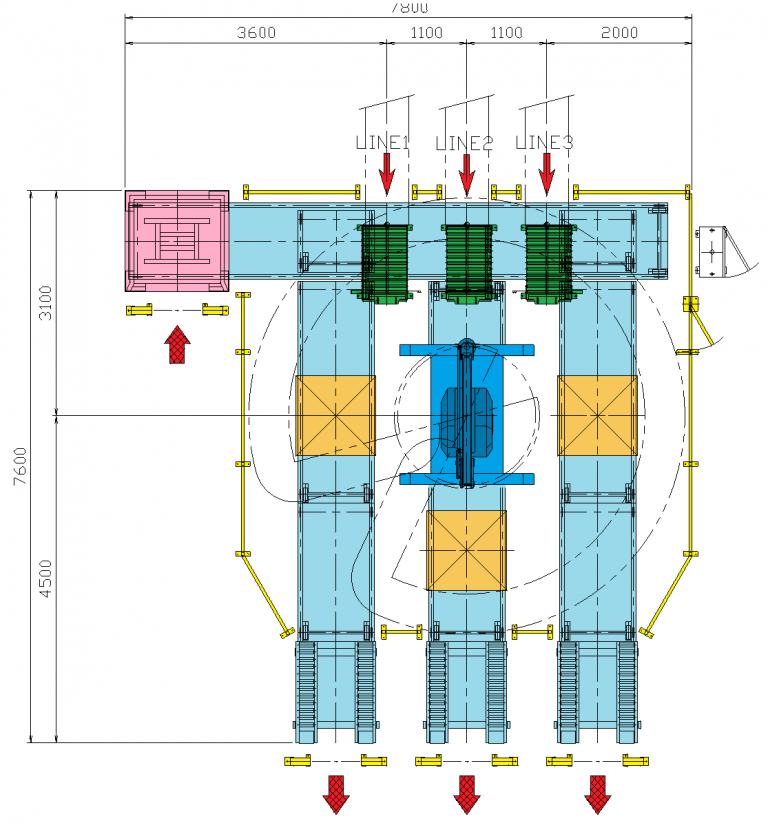

Carton/Case Palletizing

Cases and Boxes is also an area of our expertise. Choose a gripper with auto widht adjustment to hande different kinds of products at the sama time. Pick up more than 1 product at once to increase the output of your production line

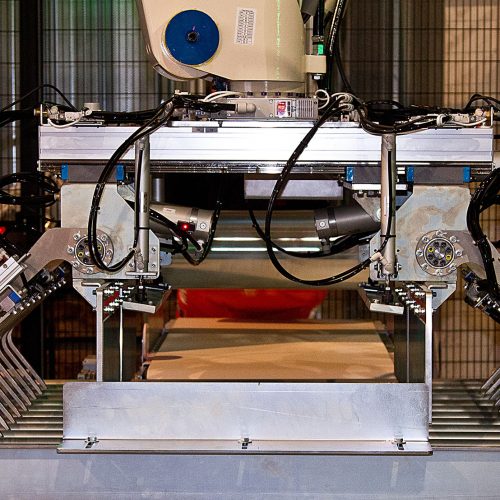

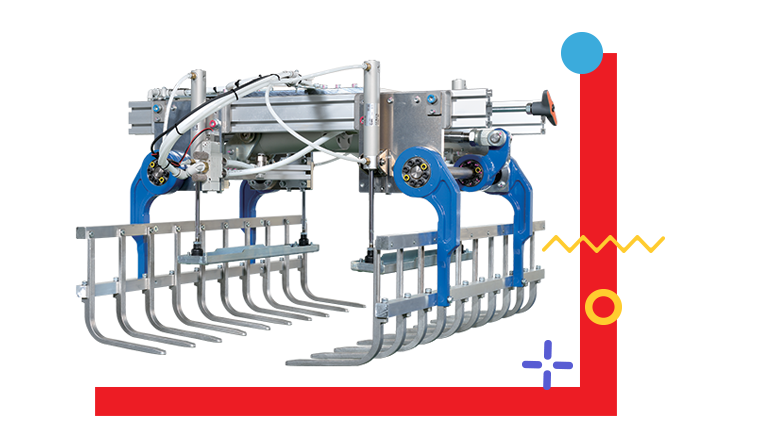

End Effectors

Fuji will provide you solution robot and gripper with a standard function package solution. Just give us your product specifications and we will find the ideal Gripper to suit your needs.